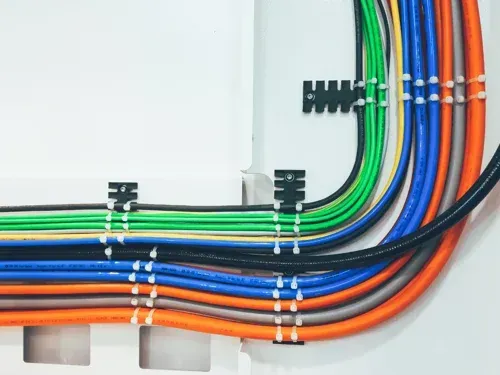

Wire Harness

Wired for Flexibility.

Auscon specializes in custom cable and wire harness assemblies for OEMs who need high-performance, application-specific solutions when standard cables don't meet the demands of their application. With automated, semi-automated, and manual (hand) tooling capabilities, we build to your exact specifications with speed, precision, and cost-efficiency.

Assembled for Durability

Our products are built to last. We use materials like nylon, PVC, and copper to meet IPC, UL, and RoHS standards. Whether your environment demands resilience to heat, abrasion, or contaminants, we engineer with protection in mind:

- Waterproofing

- Vibration and abrasion resistance

- High/low temperature endurance

- Chemical, oil, and exhaust protection

- UV light resistance

Industries Served

We proudly support a diverse range of industries, including agriculture, transportation, industrial equipment, appliances, lighting, data and communications, and sporting goods. Our flexible manufacturing capabilities allow us to tailor wire harness solutions that meet the unique requirements of each industry.

Equipment & Tooling

Cutting & Stripping

Using industry-leading wire processing equipment from Schleuniger, we precisely strip wire as small as 28 AWG and cable AWG. Hand tooling expands this up to 2/0 AWG.

Crimping

Our automated and manual crimping solutions handle a wide range of wire types and crimp profiles with accuracy and repeatability.

Soldering

We support both hand and automated soldering with options for:

- Lead and lead-free

- Selective soldering

- Wash or no-clean processes